Calibrated timber – this is some of the wood produced building materials, wooden parts (planks, beams, etc.), trimmed of the four sides of the special planing machine. The dimensions of such materials is extremely precise: if normal, non-calibrated timber may have a deviation of about 5-16 mm, calibrated timber deviation of just 1 mm. Wood calibrated already dried.

Calibrated timber – this is some of the wood produced building materials, wooden parts (planks, beams, etc.), trimmed of the four sides of the special planing machine. The dimensions of such materials is extremely precise: if normal, non-calibrated timber may have a deviation of about 5-16 mm, calibrated timber deviation of just 1 mm. Wood calibrated already dried.

In the case of a structure (such as a dwelling house) is based on a wooden construction, professional construction used only calibrated timber. This ensures the longevity of the building. The calibrated timber formed wooden construct is more stable and more accurate, and better quality. Since then, as it is designed for a static basis (as it targets how stable), depends on the thermal, insulating and other materials are used for construction quality. The more accurate the wooden frame, the easier it is to its quality and fix it on the cover material.

When the wooden frame is adopted in such materials as OSB, wood components is particularly important, because they have to be calibrated. It is also necessary to calibrate the wood, when the roof is made basis: If the base is uneven, covered with a tin, the strawberries every chase them stronger winds. In order to have a nice and smooth wooden fence, it should also be build from the calibrated timber.

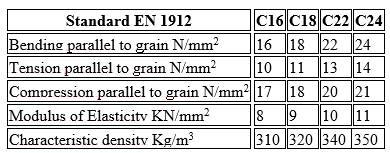

Graduated timber – is the individual pieces of wood evaluated and selected based on how much load can withstand the extent that they are resistant to bending, pressure, stretching. Graduation show marking ‘C’, and the strength of wood – next to this in the number of letters. The more the number, the larger and the strength of wooden details. Lithuania and other European countries can usually see C16 and C24, the strength of the details.

Graduated timber – is the individual pieces of wood evaluated and selected based on how much load can withstand the extent that they are resistant to bending, pressure, stretching. Graduation show marking ‘C’, and the strength of wood – next to this in the number of letters. The more the number, the larger and the strength of wooden details. Lithuania and other European countries can usually see C16 and C24, the strength of the details.

Interestingly, even the two at first glance, the same timber beams may have different strength and maintain a different size loads. Graduated wood is used where it is necessary to know in advance of wood loading capabilities – supporting constructions.

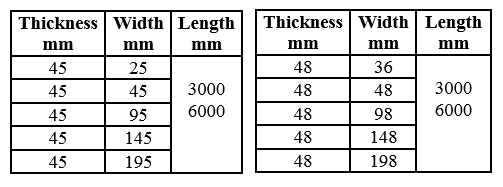

CALIBRATED (PLANED) BUILDING TIMBER STANDART DIMENSIONS:

European standard: Norwegian Standard:

JSC Torgera wood products graduate by visual criteria: a wooden detail the branches ratio (the number of branches, size and formation). Scaling performs exactly the purpose for training graduate and received a license for the employee. After graduation, they (individually) marked C16 or C24 category designation. On the wooden products also include: the type of wood; The standard by which the detail graduated, code; manufacturer and certification company identification numbers.

JSC Torgera wood products graduate by visual criteria: a wooden detail the branches ratio (the number of branches, size and formation). Scaling performs exactly the purpose for training graduate and received a license for the employee. After graduation, they (individually) marked C16 or C24 category designation. On the wooden products also include: the type of wood; The standard by which the detail graduated, code; manufacturer and certification company identification numbers.

CLASS C MINIUM CRITERIA ARE LISTED IN THE FOLLOWING TABLE: